The progresses of laser sintering of ceramics are reviewed below and a forthcoming success for ceramics will open for many applications of vast commercial values.

Laser sintering ceramic powder.

For achieving more complex geometries sls.

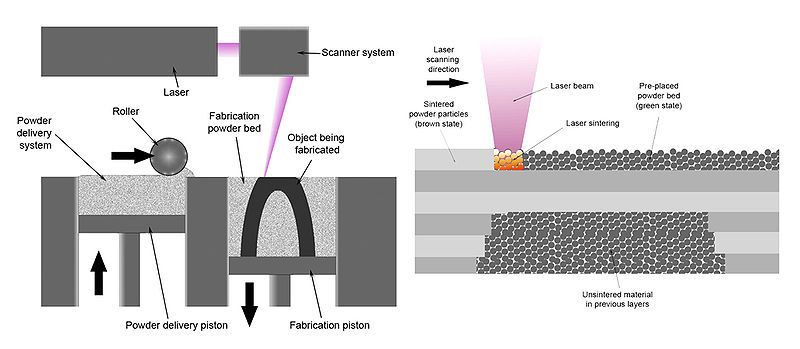

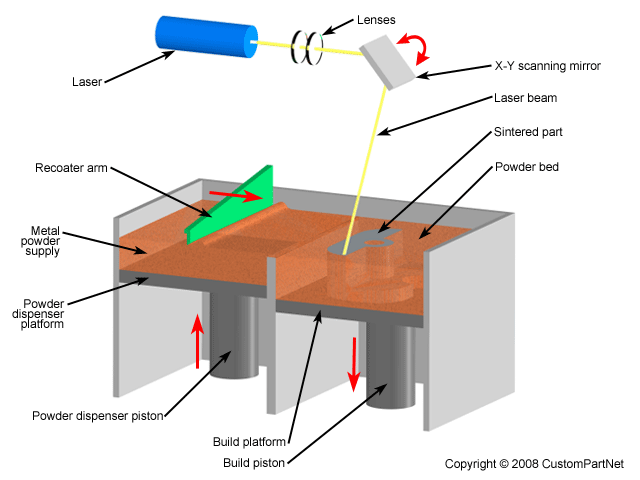

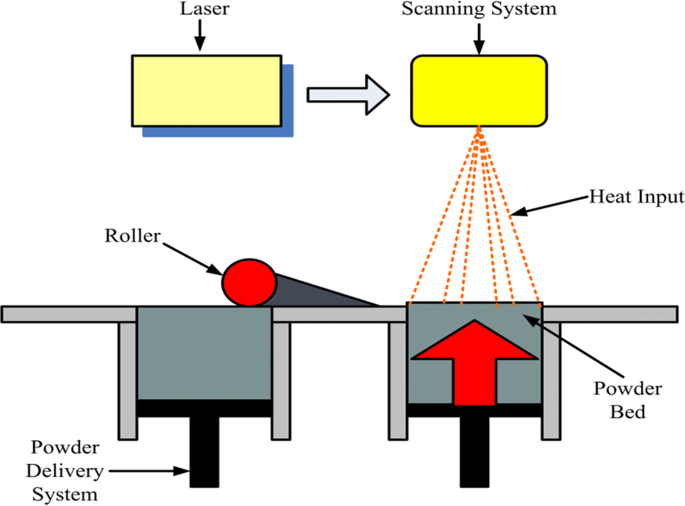

The laser sintering system in general a laser sintering system consists of a laser source a laser scanner apowderloadingunit.

Laser sintering parameters like intensity and interaction time.

Selective laser sintering melting sls m of ceramic powders is less employed due mainly to low availability of machines appropriate for ceramics laser sintering or melting.

Selective laser sintering is a powder based 3d printing technology that uses a laser to fuse material layers into a final part.

Request pdf direct selective laser sintering and melting of ceramics.

Nowadays sls along with direct metal laser sintering dmls and selective laser melting slm are some of the most significant examples of a technology collectively known as powder bed fusion.

A review this paper provides a review on the process of additive manufacturing of ceramic materials focusing on partial.

Some of them are reported in.

The same concept has since been modified to work with various materials including metals glass and ceramics.

After the laser traces a cross section of the cad design s onto a material layer the build platform lowers and another layer is fused on top.

Conditions for the selective laser induced layer sintering of a stoichiometric mixture of pbo zro2 and tio2 powders with the formation of bulk pzt ceramic articles were studied.

The laser sintering process.

Slurry based selective laser sintering sls is a technology which is a logic extension of powder based 3dp.

This paper aims to provide a review on the process of additive manufacturing of ceramic materials focusing on partial and full melting of ceramic powder by a high energy laser beam without the use of binders selective laser sintering or melting sls slm techniques are first introduced followed by analysis of results from silica sio2 zirconia zro2 and ceramic reinforced metal matrix.

The laser sintering technique uses a high energy laser beam to fuse powder granules directly into complex 3d net shape components in a layer by layer.

The proposed approach in the work combined spray drying with mechanical mixing by which we prepared a kind of compound powder consisting of epoxy resin e06 10 wt and kaolin so as to get a good fluidity for sls.

The size distribution of powder granules can be controlled as well as using homogeneous composition to avoid local tm variations.

Slurry based selective laser sintering.